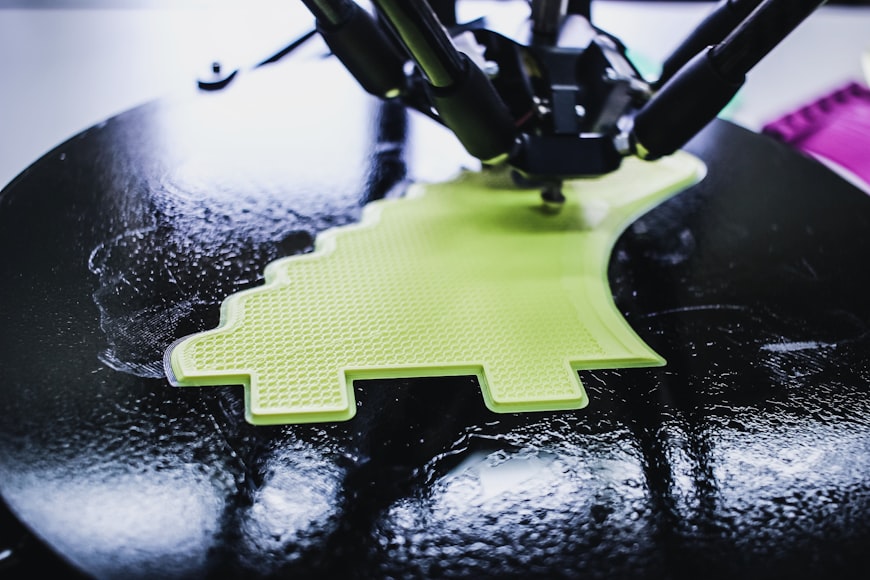

Additive manufacturing, widely known as 3D printing, has been around for some time now. This technology was first developed for rapid prototyping, and since then, it was further improved and developed by various companies looking for more efficient and cost-effective manufacturing methods.

Advancements in software, materials, and sensors have paved the way for widespread applications of this technology across different sectors. Major industries have begun to recognize the potential of this technology that encompasses all manufacturing processes.

Today, 3D printers can create incredible pieces of stuff, including furniture, robots, tools, toys, prosthetics, implants, hearing aids, houses, movie props and costumes, and even food.

Indeed, this technology has gone a long way from being just a simple prototyping machine in the 1980s. In Australia, 3D Printing Perth empowers professionals and small to large businesses to achieve greater heights by providing the best and top-of-the-line 3D printers and solutions.

3D Printing Perth: Breaking Barriers

With 3D printing, nothing seems to be impossible. There’s no limit when it comes to turning great ideas into high-definition physical reality with unmatched properties and attributes.

Advances in printing materials and technologies increase throughput, enhance productivity, and reduce manufacturing costs while minimizing waste and environmental impacts.

Major industries such as Aerospace, Automotive, and Manufacturing are turning to additive manufacturing to create lightweight parts and ergonomic designs in their quest for more sustainable business strategies..

Additive manufacturing also opens new opportunities for everyone by providing solutions to create higher quality and unique products for new and existing market segments.

3D Printers and Services in Perth

Perth has one of the best and most definitive selections of 3D printing services and printers in all of Australia, from entry-level to large-size production.

But despite the maturity and viability of the 3D printing market and the significant decrease in prices of 3D printers, some individuals and companies are still hesitant to purchase their own printers. Some preferred to outsource their 3d printing needs rather than doing it in-house.

These, however, are very understandable due to the vast spectrum of materials and processes offered by various companies. Numerous on-demand manufacturing services cover the full range of 3D printing technologies and materials, and finding one with the right capabilities for your needs is just a matter of time.

Regardless if you are after personalized parts or rapid prototyping, 3D printing services in Perth have you covered.

If you’re uncertain which print service is right for you or how exactly a 3D print service generates its prices, we suggest looking for a reputable company online and talking to one of their experts.

Where is 3D Printing Heading in the Future?

Additive manufacturing has come a long way from the early days of its introduction. As modern technology continues to evolve, the future for this technology is brighter than ever. Experts predicted that in coming years 3D printers will likely become even faster and work on larger, industrial types of projects.

Also, 3D printers will add versatility in other ways, such as using different materials within the same machine and printing a single object containing multiple materials.

Lastly, the manufacturing sector is seen to expand from using 3D printing basically for prototyping to a more substantial portion of end-use applications.