You require to maintain your hefty tools running efficiently and naturally to stay clear of job delays. For your fleet, you could not stint upkeep. Staying on top of the operation of construction tools is virtually as vital a task as utilizing it.

Why Machinery Maintenance Is Important?

Maintenance comes in various forms— responsive and preventative. Responsive care happens when your devices run into problems such as reduced oil levels troubles from fuel contaminants in the gas. Though the device might not break down, it would still experience sufficient trouble to need service before working at its most significant performance. Usually, responsive upkeep happens after a breakdown, thus requiring a quick response.

While this kind of maintenance would get your machine back right into operation, you shouldn’t respond to problems regularly. Doing this will halt work with the non-functional equipment till it gets dealt with. Relying on the seriousness of the problem, the repair work time might take away time from the project. Instead of waiting on parts of the fleet to go out of command, consider taking an extra proactive method with preventative upkeep.

Protecting against issues will conserve money and time because you’ll service building devices before losing performance and efficiency. Frequently servicing equipment would undoubtedly keep it in peak condition. Preventative upkeep must be your preferred strategy because, in the building sector, running tools to the point of letdown produce a lot more issues than the minor aggravation of setup maintenance.

Routine Upkeep

Responsive upkeep jobs take place when an issue starts to emerge. Responding to the concern requires discovering the reason as well as repairing it. Minimized gas quality, low oil, and blocked filters often trigger problems when left uncontrolled. If trouble occurs, inspecting the rest of the automobile for expanding worries should be a part of tough chores.

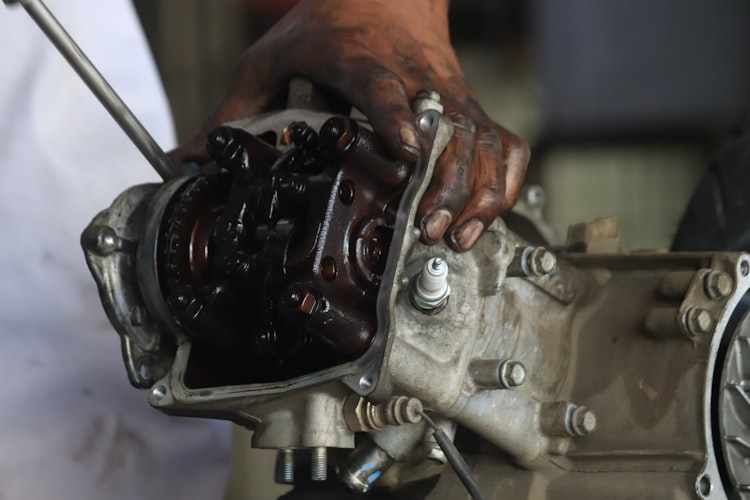

The specific upkeep jobs will certainly depend upon the vehicle and the supplier’s suggestions. Nonetheless, the majority of pieces of heavy tools have engines that require similar checks made. For regular upkeep of heavy machinery, examine the following:

Oil: Validate that the system has sufficient oil which the oil’s quality is satisfactory.

Fluid degrees: Take a look at the coolant, oil, fuel, and fluid levels to find out if they’re high enough. Regular drops in liquids show a leakage someplace that you have to repair.

Working: Do all the components relocate as smoothly as they need to be? Do the controls function appropriately? Troubles with the elements might suggest problems with the device workers on the machine.

Appearance: During the aesthetic evaluation, trying to find anything that seems out of place could make finding issues simpler.

Preventative Upkeep

Machinery maintenance takes place on a timetable no matter whether the machine shows troubles running or otherwise. By implementing a regular examination into your company’s repair service as well as an upkeep schedule, you’ll make sure that the equipment would certainly not need to stop work before getting attention. The outcome will undoubtedly be a boost in uptime as well as productivity. With lots of elements that can create lost time on the construction tasks outside of your control, like stormy weather, preserving your fleet is one vital point to keep in mind if you wish to protect against lost time.