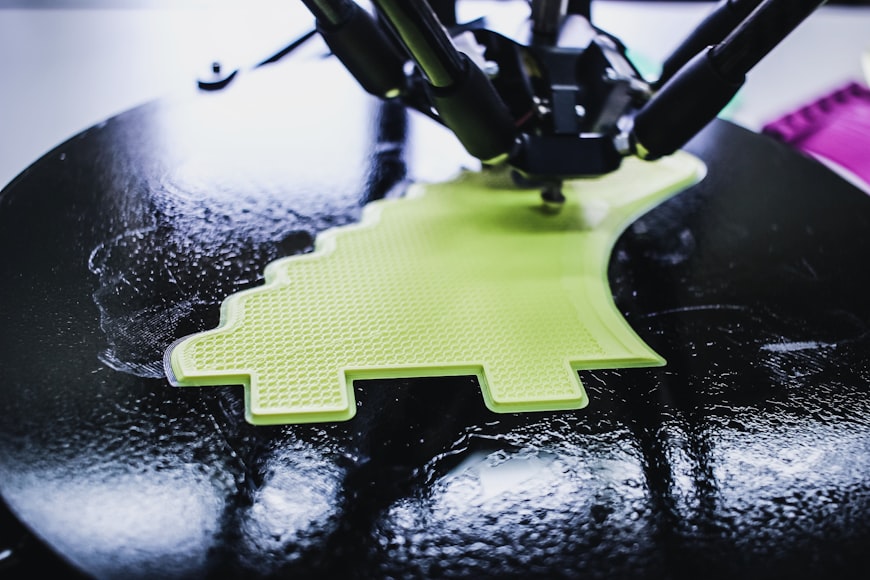

A lot of businesses have a 3D printing option that they utilize daily. Carrying out appropriate 3D printer maintenance will undoubtedly guarantee that your printer maintains running efficiently and continues to toss out components in the most effective feasible type.

Commercial 3D Printer Maintenance

PolyJet 3D Printers-Maintenance Tips

For PolyJet 3D printers, it’s specifically crucial to keep the heads and your device tidy, and this will maintain your machine performing at its leading performance.

Do Away with Particles

Another excellent tip for maintaining your PolyJet maker is to clean out the material particles that accumulate within the chamber. As you eliminate parts from your equipment, small items of assistance products usually fall and scatter throughout the maker. Vacuuming out and cleaning down the device will make certain material doesn’t accumulate and get caught in the bearings or sensors.

Keep it Running

One last suggestion for PolyJet machines is to run them a minimum of as soon as a week. When a component is running, it aids to keep the material streaming via the lines and through the heads. Material that sits still for too long can influence develop high quality. So if your maker has been idle for a couple of days, begin a tiny build and let the equipment run.

FDM 3D Printers- MaintenaceTips

Regular Tip Modifications

Doing a tip adjustment when it’s time will ensure your material flows correctly and you don’t end up with any failed builds. The time between idea adjustments can vary depending upon what FDM equipment you possess. Yet, the software will certainly send you a friendly time when the time has come. So, if you do obtain a warning message to change the ideas, reserve a few minutes and obtain a new tip in there.

Utilize a Brand-new Tray

It is recommended to use a brand-new tray inside Stratasys uPrint, Stratasys Dimension, and Stratasys F-Series 3D printers to maintain the parts. When a tray is reused, the surface monotony is impacted, which can impact the high quality of the print (or can protect against the print from starting at all). Utilizing a new tray makes sure that the component sticks as planned and completes with no concerns.

Vacuum Builds Envelops

Vacuuming your developed envelope will undoubtedly help keep the small pieces of product that accumulate in time far from the sensors and help avoid prospective mistakes. Most of the motion mistakes that occur on FDM machines are because some product remains in a sensing unit or obstructs a sensor from being stumbled upon when needed. By vacuuming out your envelope, you can prevent the error from returning.

Follow the Prompts

A commercial 3D printer comes with maintenance motivates for you to adhere to. When a timely turn up to change the ideas, change or check your suggestion wiper or states there is a firmware upgrade offered to care for it promptly. The earlier the timely is resolved, the better off you are. Idea wipers are an integral part of keeping your ideas clean and also aid ensure build quality.