If you can imagine it, you can design, develop and manufacture it with 3D printing Brisbane.

Advancements in 3D printing technology have made it easy for designers and engineers to create a wide range of complex and versatile products faster and cost-effectively.

Indeed, this breakthrough technology has gone a long way since its introduction. From creating physical prototypes at different scales to producing structures that are impossible to build with standard manufacturing techniques, additive manufacturing is making progress as cutting-edge technology.

This article is for professionals and aspiring entrepreneurs who want to work in the 3D printing industry to advance their business and career goals.

What is Additive Manufacturing?

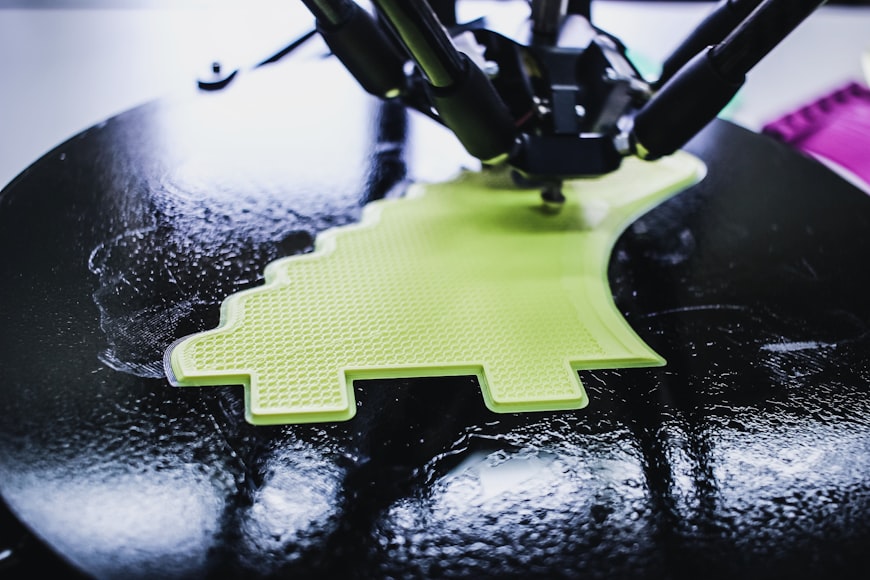

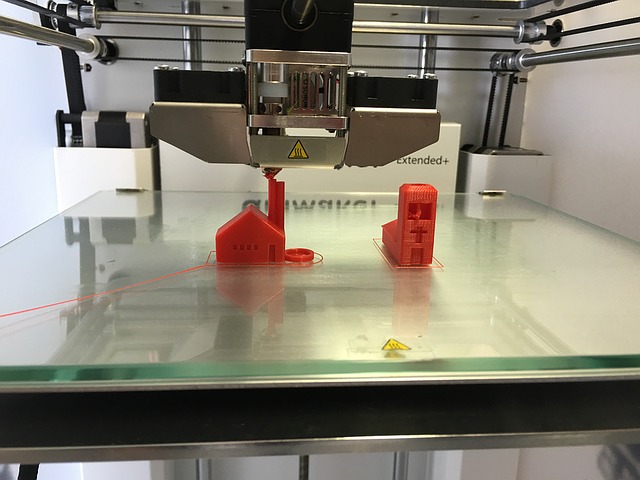

Additive manufacturing or 3D printing is a process where a digital model is turned into a tangible, solid, three-dimensional object by laying down many successive, thin layers of industry-grade material.

This manufacturing method has become quickly popular because it makes manufacturing more accessible to the public than ever before.

The Additive Manufacturing Process

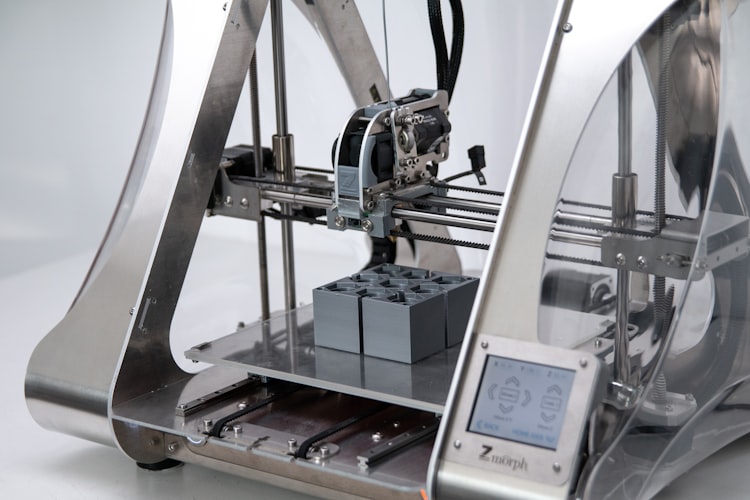

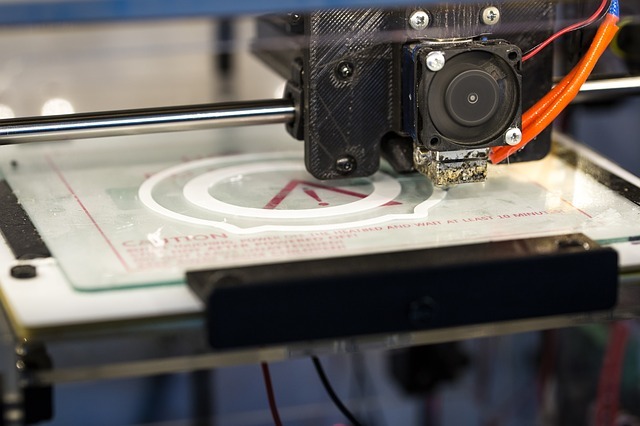

The additive manufacturing process starts with the designer’s imagination or idea of a product. Using computer-aided design (CAD) software, these ideas are turned into a virtual design or 3D model.

Aside from CAD software, these virtual designs can be created using a 3D scanner where an object is scanned from different angles.

Once the 3D model is made, it is now prepared for printing by breaking down the virtual model into several layers using a process called slicing.

After the 3D model has been sliced, they are uploaded to the 3D printer using a USB cable or Wi-Fi connection. Once uploaded to the 3D printer, it reads every slice and prints it layers by layer using different materials to create a structure from scratch.

What Things or Products Can Be 3D Printed?

With additive manufacturing, imagination is the limit. Anything that you can possibly imagine can be turned into a design that can be 3D printed.

The latest 3D printers and scanners are helping designers, engineers, and even ordinary people to design and develop complex objects in ways that traditional manufacturing methods aren’t capable of.

From toys, food, and tools to clothing, tables, lamps, pottery, art, and even cars can be 3D printed. The dental and medical field is also looking for new ways to use this technology to help patients. Medical professionals can customize medical and surgical models essential for a practice run before the actual operation on the patient.

These 3D printed models are also used to create less expensive but durable and better-fitting prosthetics for patients.

The Effects on Manufacturing of 3D Printing Brisbane

The various applications of additive manufacturing impact the way the products are manufactured by bringing the production closer to the consumer and reducing the current supply chain restrictions.

The ability of this technology to produce products in small batches and allow faster customization with precision is a sure way to engage consumers.

The logistics and shipping costs of various spare parts and products are eliminated because spare parts can be 3D printed on-site.

Lastly, shapes and geometries that seemed to be previously impossible to create can be produced with a 3D printer. Additive manufacturing has the potential to infuse growth into innovation and boost local manufacturing.

Summary

With all these benefits and values, additive manufacturing continues to evolve with a lot of exciting potential for the future. It is only the beginning of many more possibilities that can make our lives easier, more convenient, safer, and healthier. The versatility of this technology and its capabilities make it a field filled with opportunities for everyone.