3D printing is increasing innovation in various markets, consisting of dentistry, glasses, prosthetics, furnishings style, paleontology, archaeology, and forensic sciences. As well as we’re simply beginning with understanding the unlimited possibility of 3D printing on substantially improving the means we work and live.

3D Printing: What Is It?

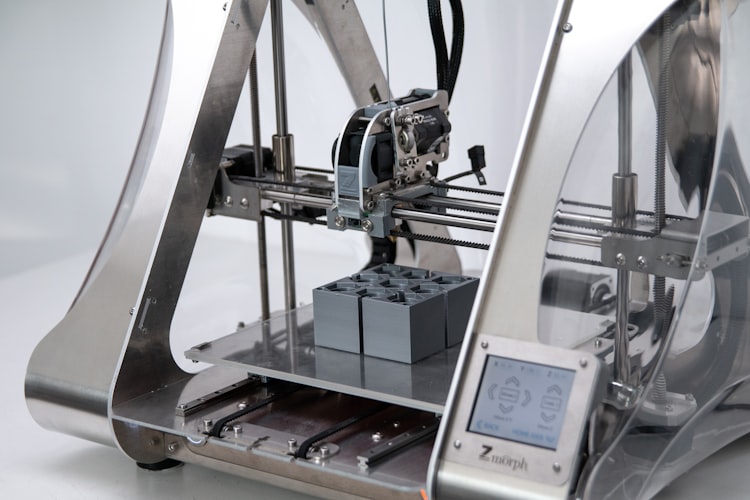

3D printing could take various procedures in which a component is additively developed by presenting or bonding added products. 3D published items can be complex and also are suitable in a wide diversity of making applications. Machines could set you back numerous dollars and utilize various modern technologies to publish parts.

Additive production is where a part is made by including a product, whereas the subtractive industrial process is made by subtracting the product. A 3D printer makes three-dimensional things by beginning with a CAD file. There is a diversity of products and 3D printing innovations readily available, thus making it easier than ever before to create components for all kinds of markets.

3D Printer Brisbane: Utilized for Production

While 3D printing is linked to various items such as toys, they are more capable of creating parts that could withstand a wide variety of durable atmospheres. You can discover 3D published components being made use of in manufacturing procedures in industries like automotive, energy, and protection. The 3D printing sector is transforming numerous other businesses and procedures from practical prototypes, tools, and fixtures to end-use parts.

Nowadays, businesses worldwide use 3D printers to develop parts for industrial purposes with considerable enhancements to 3D printing expenses. A big part of the growth in the 3D printing industry originates from a surge in using 3D printing in manufacturing; something formerly thought impossible when the procedure caught on.

Most Typical 3D Printing Technologies

While there are several 3D printing strategies, here are the common kinds. All printing technologies develop components in distinct pieces called layers.

Fused Filament Fabrication

It is the most typical and budget-friendly kind of printing, and many types of equipment utilize this modern technology. The printer heats thermoplastic to a near-melting factor and extrudes it out a nozzle that traces the cross-section of a component for each layer. This procedure repeats for every layer.

Continuous Fiber Reinforcement

It is a process that makes it possible for 3D printers to strengthen FFF and get rid of straight fibers. A CFR-capable device uses two extrusion systems– one for traditional FFF filament and another for long-strand continual threads. Continual fibers are put down in-layer, substituting FFF infill. The results are more vital and can change lightweight aluminum parts in the application.

All-time Low Line

Numerous firms locate that adding printers to the manufacturing procedure can substantially lower the time invested in making intricate components in-house. 3D printer Brisbane could produce parts quicker and also at an inexpensive price for personalized, low-volume parts. Services can concentrate on revenue-making, money, end-use aspects instead of spending time, and initiative on low-volume components that may not produce any income. With a 3D printer Brisbane, you can swiftly repeat styles without wasting resources awaiting parts that may not fulfill quality requirements. This makes printers ideal for custom-made models, low-volume, tooling, and components that are usually complicated and tough to equipment but are serious for a reliable production process.